Challenges

There was no margin for error, any precipitation on the roofing membrane would have adverse effects on the protective capabilities of the coating material and result in it to be redone. The project had to be completed without schedule delays.

Actions:

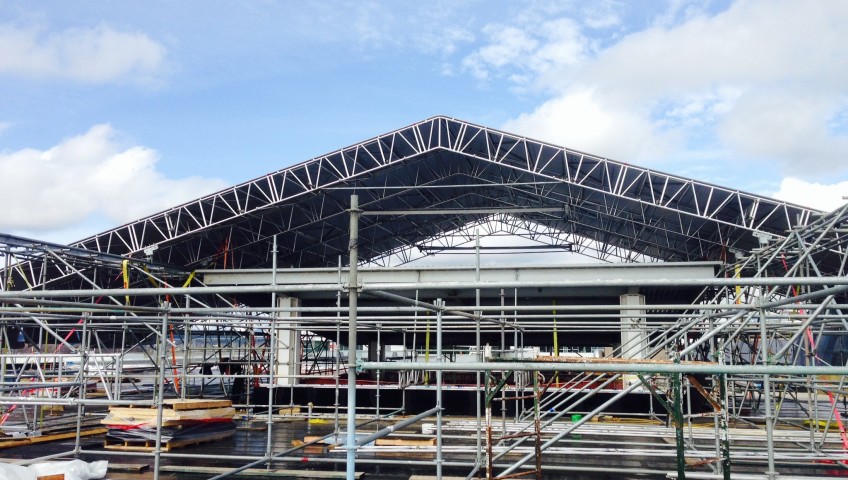

A lean to roof (mono pitch) was erected running from the existing building out to the sidewalk. It was supported using a series of scaffolding towers, tied together using various supporting 750 beams. Weather protective sheeting was used to cover the roof structure and ensure it was rain proof.

Results:

The roofing solution meant that the weather protective membrane applied was successful due to eliminating all weather risks. The task was completed on schedule without delays or reworking.

“The innovative solution to the project ticked all the boxes for us in terms of allowing the restoration works to be completed throughout the winter period and within schedule. It was completed safely, on time and within budget.”

“The innovative solution to the project ticked all the boxes for us in terms of allowing the restoration works to be completed throughout the winter period and within schedule. It was completed safely, on time and within budget.”

“On a project where schedule could not be compromised, the enveloping of our structure allowed for the building to be built from the inside out, and allowed for scopes typically governed by weather to proceed. This contributed to the recovery of several months in delay which otherwise would not have been avoided. The roofing product surpassed my expectations and consistently delivered quality workmanship while maintaining and complying with all safe work requirements on site. “

“On a project where schedule could not be compromised, the enveloping of our structure allowed for the building to be built from the inside out, and allowed for scopes typically governed by weather to proceed. This contributed to the recovery of several months in delay which otherwise would not have been avoided. The roofing product surpassed my expectations and consistently delivered quality workmanship while maintaining and complying with all safe work requirements on site. “